9 facts about refurbishing

e-bike batteries

What should you pay attention to when you have an e-bike battery refurbished? How do you know if a battery refurbishment is carried out properly? Specialist Hannes de Jong offers his insights with a tour through the world of battery refurbishment. "Refurbishing e-bike batteries is a wise choice, but it's important to pay attention to quality."

_w878_h646_1.jpg)

Hannes de Jong owns Heskon, an online e-bike battery refurbishing platform for bike dealers. De Jong has been working with lithium-ion batteries for about ten years and has a thorough understadning of the ins and outs of the refurbishing process. When asked whether refurbishing batteries is a sensible alternative to a new battery, he answers wholeheartedly yes. “But it is essential that the revision process is done properly. And - to be fair - as a dealer, that is difficult to judge. An insight into the refurbishment process can, however, help you with that assessment.”

Look through the 9 facts about battery refurbishing.

FACT 1

Intelligent BMS is difficult to repair

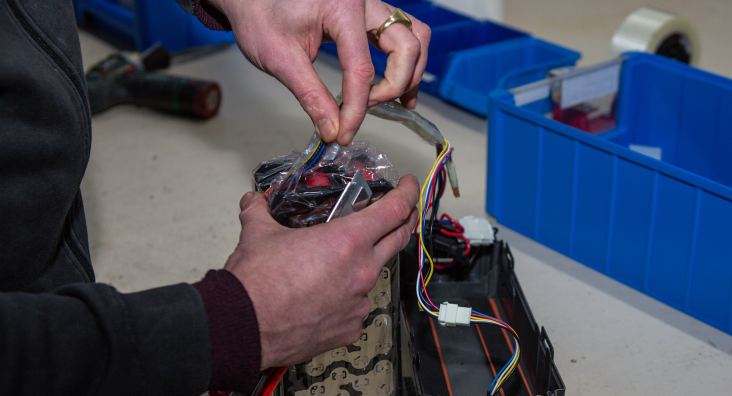

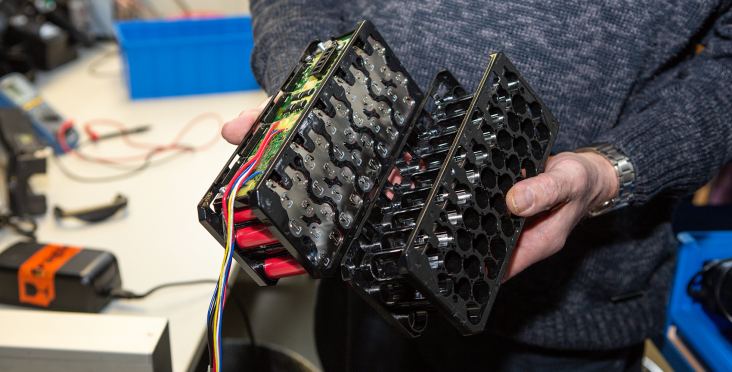

Before Hannes de Jong dives deep into technology, he explains how a bicycle battery works. “An e-bike battery consists of the housing, the cell pack - which almost completely fills the housing - and the battery management system (BMS). The housing ensures that no moisture can get to the cells and that the battery is safe. The BMS ensures that the battery is properly charged and delivers the correct amount of power to the motor. In terms of the BMS there are three types: the non-intelligent, partly intelligent and the intelligently communicating BMS. The non-intelligent BMS only performs the most essential safety functions and does not discharge the cells too deeply or evenly. From 2020 this BMS may no longer be sold on a new bicycle.”

Often the terms repair and refurbishment are mentioned in the same breath. But they are completely different actions. Hannes de Jong: “You refurbish something that is worn out. During a repair you fix something that is broken. For example, if the housing is torn, you can replace it with a new one, provided you have one of course. The rule of thumb is that if a battery does not work from one day to the next, a refurbishment is not a logical option. In this case, repairing - replacing a broken cell or broken BMS with a new one or used, for example - or replacing the battery, is the solution. If the battery is just performing a little less than before, refurbishing does offer a solution. Refurbishing is nothing more or less than the preventive replacement of all worn parts. Whereas, with replacing, you replace all cells, and not just the few worn-out cells like with an overhaul.”

FACT 3

Always refurbish with new cells

Worn out cells are replaced during a refurbishment. According to De Jong, it is essential that the cells are replaced by new ones of the same brand and type. This does not always happen in practice. “In my work, I regularly see batteries that are equipped with different brands and types of cells, which are sometimes even used. My advice is never to do a refurbishment with used cells. Also make sure that no ‘new’ cells are used that have been shelved for years. These cells have already been considerably reduced in capacity by laying still for long. Refurbishing a battery takes a lot of time and therefore money. Then it is a shame to only replace the worn-out cells with already used ones because after a while, the battery will die again because other cells will give up.”

FACT4

Cells are not bought on the corner of the street

The availability of cells is a problem. Hannes de Jong: “Anyone who only refurbishes a few batteries only needs a few hundred to a few thousand cells every year. However, large suppliers are not keen on supplying small quantities of them. The result is that these battery refurbishers buy larger quantities. Sometimes these are cells that have been used but are being sold as new. It is a bit of a grey area but it creates an element of risk. If you outsource the battery refurbishment, you don't know exactly what the quality of the cells will be.”

FACT5

Bad spot welding and soldering is a guarantee for disaster

The quality of the refurbishment and thus the safety of the battery largely depends on the spot welding of the cells. Hannes de Jong: “The batteries are connected by means of strips, which are spot welded on the battery. If new strips are only added to the replaced cells rather than the complete pack, there is a good chance that the strips will come off due to the rattling of the bicycle.

This can then short circuit and create the risk of a battery fire. Another point of attention is the quality of the soldering of, for example, the wires and the BMS. That must be good, so there is no risk of short-circuiting. Finally, the battery must be assembled properly. If the cells are not tight enough in the housing, everything will rattle. This in turn increases the risk of a short circuit. When assessing the quality of a refurbishment, make sure that the battery is neatly sealed or splash-proof. This is because a fire can occur when moisture enters.” De Jong further emphasises that the sheath of the cables must always be intact. The wire should never be visible, as there is a risk of a short circuit. It is important that the cable is correctly mounted and not becoming defect in the housing.

Every battery that Hannes de Jong receives for a refurbishment is first tested to check whether the battery is malfunctioning or whether it is simply worn out. “After the battery has been completely refurbished, it is subject to a severe stress test. The test computer loads the battery up to 15 Amps to see whether the battery performs well under severe conditions. Checks include whether the cells don't become too hot while charging and that the BMS switches off if the power becomes too much. The stress test gives us certainty about the operation and safety of the battery. Based on this, we can actually give a two-year warranty." Heskon often also tests the battery on a bicycle that they have in the workshop, to check that the communication between battery, display, motor and sensors is working properly. "Finally, the visual check follows and then the battery is returned to the customer."

FACT7

Bicycle batteries require special transport

The transportation of e-bike batteries is often neglected, says De Jong. “E-bike batteries must be transported in accordance with the rules of ADR legislation, the pan-European treaty for the international transport of dangerous goods by road. Because the products are flammable, it is imperative that the persons transporting them are aware of this. E-bike batteries must be provided with special stickers with the indication UN3480. A well-known carrier of batteries in the bicycle industry is, for example, Mikropakket.”

FACT8

Guarantee should also include battery operation

With a refurbishment, there is also the question regarding guarantee status. “There is a difference between giving a guarantee and receiving a guarantee. At many companies you only get a guarantee on the operation of the cellular package, not on the operation of the battery. It is important to pay close attention to that. Also pay attention to whether you have to pay transportation costs when you have a battery refurbished."

FACT9

Quality is not always evident

Refurbishing an e-bike battery is a wise choice, according to De Jong, but there can be pitfalls. “You have to pay attention to where the refurbishment takes place and ask the right questions about the testing process and safety. Also discuss matters such as timeframe; do you have certainty that batteries will be returned within a few days? My advice is to find a company that is also a knowledge centre and avoid parties that act more as hobbyists.”