Unique facility in Leuven

Belgium Takes Carbon Frame Production to the Next Level

Continue reading

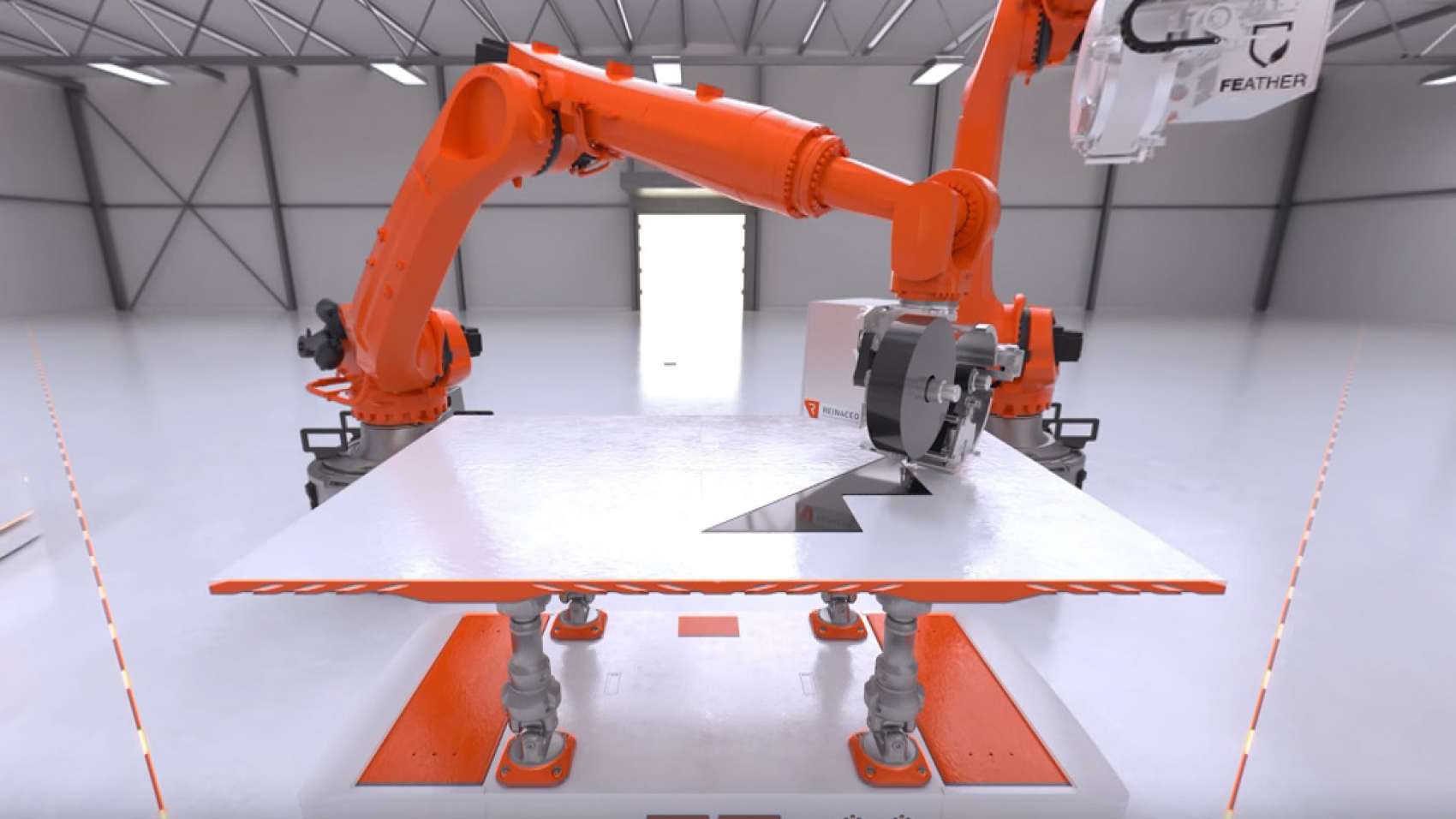

REIN4CED Opens Fully Automated Composite Frame Factory

LEUVEN, Belgium – REIN4CED has festively opened its bicycle frame production facility in Leuven, Belgium. With this unique facility, REIN4CED is closing into the final straight of its mission to bring back carbon bicycle frame production to Europe.

Despite being the heart of cycling, all bike used in the Tour de France, which started in Brussels at about the same time of the REIN4CED opening, are crafted in Asia. The REIN4CED team which invented the unbreakable composite frame material, presented a sneak peek into its automated bicycle frame production line that is currently being set up.

Starting at the end of this year REIN4CED will supply its unbreakable frames to the leading cycling brands. With its Leuven, Belgium based new facility the company can offer significant logistic advantages and increased supply chain flexibility and efficiency to European based bike brands.

Next carbon material

The new production plant for innovative bicycle frames is a major milestone in the growth path of REIN4CED. “Already late 2019, our first unbreakable carbon frames will roll off the new production line,” says Dave Luyckx, CPO REIN4CED.

“Key in this regard is the development of a new impact-resistant composite material. The disruptive material of REIN4CED eliminates the sudden and dramatic failure of carbon bicycle frames that put riders’ lives in danger. The new lightweight material combines carbon with fine steel fibers, offering cyclists maximum performance with enhanced safety and durability.”

The REIN4CED executive continues “Currently, REIN4CED is setting up series production of innovative carbon bicycle frames in its new facility in Belgium. REIN4CED is actively engaged in advanced discussions with multiple world-leading cycling brands that want to incorporate REIN4CED’s patented impact-resistant material in their portfolios.”

Ramping up automated frame production

REIN4CED will kick off production with an annual production capacity of up to 20,000 bicycle frames in 2020. Subsequently the facility will be able to support increasing production volumes needed to respond to the growing demand for localized production in Europe.

REIN4CED CEO Michaël Callens: “Today, race bicycles and mountain bikes are crafted manually in Asia. The innovation-centric production facility enables REIN4CED to bring composite bicycle frame production back to Belgium, the cycling country par excellence. Located centrally in Europe, and less than twenty kilometers away from Brussels international airport, the facility in Leuven enables REIN4CED to flexibly host bicycle industry delegates and ship frames internationally.”

About REIN4CED

REIN4CED is a Belgium-based company that has extensive expertise in composite manufacturing and bicycle frame development. It has developed and patented a new fiber-strengthened composite material which is being brought to an industrial scale. In its new production facility, REIN4CED will manufacture impact-resistant and lightweight bicycle frames for brands wishing to offer their cyclists maximum performance with enhanced safety and durability.

_w510_h510_1.jpg)